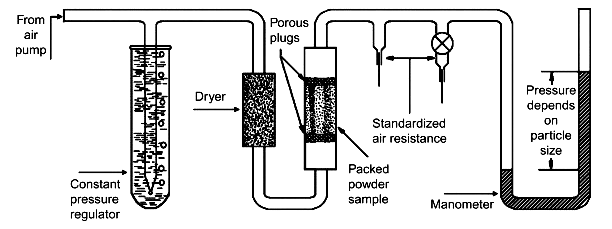

Air permeability can measure particle size because the size and number of pores in a powder bed determines the rate at which air flows through it. The air permeability method measures the pressure of air that passes through a packed bed of powder, and then calculates the average particle size from the transmitted pressure and the powder's specific surface area.

Air permeability is a non-destructive testing method that's quick, accurate, and repeatable. It's also cost-effective because it doesn't require the powder to be exposed to gases or a vacuum, which can make it unstable. The results of air permeability tests can be used to predict powder performance, evaluate product quality, and assess manufacturing consistency.

Measuring Range: 0.1~100 micron

Porosity Range: 0.25~0.95

Repeatability: ± 3%

Power Supply: 220V, 50Hz

Power Consumption: 60W

working temperature: 25 ± 10 °C

Weight: 18 kg (WLP-216) + 2.5 kg (notebook PC)

Outline: 445 x 240 x 400 mm

This AutoFSSS works with laptop computer, suitable for measurement of metallurgy powder, refractory powder and magnetic material, including Molybdenum powder, Tungsten powder, Titanium powder, Nickel powder, Alumina powder, Silica powder, Magnesia powder, Zirconia powder, Chromite powder, Nickel powder, Cobalt powder, Ferrite powder, NdFeB powder, Iron oxide (Fe3O4 or Fe2O3) powder, etc.

This automatic Fisher Sub Sieve Sizer can show measuring results directly on screen. No potential eye-watching error any more. Provide specific surface area directly without manual calculation.

It enables you to easily save or print out measuring results. This point has become a basic requirement in nowadays working circumstances.

Even though we said one thousand times that the quality is no doubt, you may still hesitate. If you like, you can send us some of your powder samples and tell us their density, then we will provide you with the measring results including average particle size, specific surface area and porosity. Then you can rest assured that it is absolutely the best.

We even met such a case that sounded interesting. One customer sent us his powder samples and when we informed him of the measuring results, he said our measurements were incorrect. But eventually, he came to realized the fact that our data was accurate and it was the old records he kept were wrong.

We think there are two reasons causing this case. One reason is the standard tube (also called regulation tube) for existing old machine was out of service life. Its accuracy has become less. The other reason is the reference powder sample is not fresh any more as time passed by. The powder became sticking to each other into small blocks.